INSIGHTS ON PHARMACEUTICAL INSPECTION

-

Test Kit Management: The Hidden Weak Point In Your Visual Inspection Program

A proper test kit management program is no longer a “nice-to-have”—it’s a compliance necessity. Without a structured system, you risk inspector drift, failed audits, and errors in batch release.

-

Guide To Product Inspection Systems In The Pharmaceutical Industry

Explore the critical role of inspection systems, specifically metal detectors, X-ray systems, and checkweighers, in pharmaceutical manufacturing.

-

Understanding Injectable Drug Container Closure Systems

Choosing the right container closure system (CCS) format is crucial, so understanding the different parts involved, their functions, storage requirements, and how they impact administering the drug is essential.

-

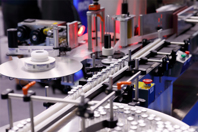

Find Flexibility And Scalability With Modular Assembly Equipment

Find tailor-made solutions designed to deliver high-quality standards even when scaling up. Modularity enhances production efficiency, saves costs, and shortens time to market.

-

Determining The Limit Of Detection In CCIT12/18/2025

Accurately determining the smallest detectable defect in pharmaceutical packaging is essential for sterility. Learn how test sensitivity, positive controls, and regulatory standards shape CCI strategies.

-

A Closer Look At Inspection Systems In Tablet And Capsule Production8/29/2024

Walk through the rigorous inspection process pharmaceutical products undergo to ensure safety and quality, from granulated ingredients to packaging.

-

The Significance Of Preventive Maintenance For Product Inspection Systems10/9/2024

Watch to gain insight into the crucial role of maintenance in ensuring the ongoing optimal performance, reliability, and longevity of your inspection systems.

-

Pharmaceutical X-Ray Counts Capsules And Pills8/15/2025

See how advanced x-ray inspection technology verifies correct pill count, identifies broken capsules, and detects foreign contaminants in pharmaceutical sachet packets.

-

A Complete Guide To Capsule Checkweighing5/2/2025

Understand why accurate capsule weighing is essential for therapeutic efficacy, safety, and adherence to pharmaceutical manufacturing standards.

PHARMACEUTICAL INSPECTION SOLUTIONS

-

Flawless tablet production starts with precision CT scanning. Uncover hidden defects, ensure product integrity, and deliver quality every time.

-

With an extended portfolio and a wide expertise in advanced inspection technologies, we can deliver flexible inspection solutions at any stage of the product journey; from lab development to high volume production.

-

Packaging is essential for the safe storage and administration of pharmaceutical products. Learn about a non-destructive micro leak detection device for testing container closure integrity and package integrity.

-

The XR75 Pharma X-ray is optimized for the quality control of pharmaceutical, nutraceutical, and cosmetic products in thin opaque packaging materials that cannot be inspected manually or with visual systems. The leakage prevention curtains are designed to leave a 10 mm-clearance that ensures safety and reduces false rejects caused by product jams or changed orientation during conveyance. The system checks for different product integrity issues simultaneously: products trapped in seals, missing, chipped, or broken tablets in blisters, and the presence of foreign contaminants. The high-resolution X-ray images ensure reliable inspection of the small items at belt speed up to 90 m/min.

-

Used Mettler Toledo Safeline metalcheck, model 2S, CE rated, 240 volt, serial# 121323, built 2014.