INSIGHTS ON CRITICAL ENVIRONMENTS

-

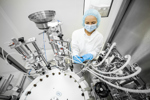

Practical Considerations For Aseptic Gowning In Contamination Control Strategies

Master the complexities of aseptic gowning and Annex 1 compliance. Explore risk-based strategies to mitigate human-source contamination and strengthen your facility's sterility assurance.

-

0.45 m/s ±20% At Working Position In Closed Sterility Testing Isolators: Requirement Or Convention?

Balance compliance and efficiency in sterility testing. Explore how a risk-based approach to airflow and isolator technology aligns with Annex 1 while optimizing contamination control.

-

What Happens When You Refuse To Compromise On Sustainability?

Discover how an empty building shell became a sustainable nanomedicine hub and achieved 47% energy savings and 88% fewer emissions, which sets new standards for innovation in the biologics industry.

-

Driving Continuous Improvement: Pushing Through The Barriers To Change

Discover how continuous improvement drives efficiency in pharmaceutical manufacturing. Learn strategies to harmonize processes and reduce environmental impact in this thoughtful exploration.

-

The Pain Of Change – Could Suppliers Be Part Of The Cure?10/15/2024

Change is a constant in the pharma industry, but it doesn't have to be painful. Discover how suppliers can help ease the burden of regulatory change management and streamline essential processes.

-

The Impact Of AI In Biopharmaceutical Manufacturing4/16/2025

From automating repetitive tasks to optimizing complex bioprocesses, AI is reshaping biopharmaceutical manufacturing. Discover how AI is moving beyond trends to become a foundational element in the industry.

-

Increase Agility By Integrating Drug Substance And Drug Product1/9/2026

Biopharma success depends on agility. Move efficiently from discovery to delivery by co-locating drug substance and drug product operations, reducing transfer risks and accelerating your timeline

-

What Is OPC Counting Efficiency?6/24/2025

Ensure cleanroom air quality with optical particle counters. Explore how OPCs work, their performance metrics, and key considerations for choosing the right one.

-

Automation-Assisted Washing Of Multicellular 3D Spheroids11/7/2025

Automated washing of 3D spheroids improves consistency, reduces cell loss, and streamlines staining workflows. See how this approach enhances reproducibility and throughput in microplate-based assays.

CRITICAL ENVIRONMENT SOLUTIONS

-

Ensuring your equipment remains in optimal condition is vital for speed, accuracy, and productivity. Explore a preventive maintenance service that is integral to reduce breakdowns and maintain high-quality standards.

-

The TSI AeroTrak 9303 Handheld Particle Counter offers the most features and flexibility for customers interested in a low cost and versatile handheld particle counter. The Model 9303 features a sturdy yet lightweight high-impact injection-molded plastic design for easy handling. The instrument is easy to configure using an intuitive keypad. The internal memory can store up to 1,500 sample records of particle count data which can be conveniently viewed on screen or downloaded using a USB port.

-

Benefits of TSI's unique FMS 5 product offering.

-

From bioprocessing to compounding, discover a complete ecosystem of life science tools. Ensure safety and sterility with advanced containment and laboratory solutions.

-

The AES litebeam is a patented and one-of-a-kind 4” [100mm] wide linear LED light which is fully flush and integrated into the 3” [75mm] AES marquee ceiling system, providing a fully flush surface on both surfaces of the ceiling. These lights have a lighting level dimmable controller, and provide greater flexibility when locating HEPA air filter diffusers in the cleanroom ceiling system.

FREE CLEANING VALIDATION E-BOOK

Learn how to employ science-, risk-, and statistics-based approaches to cleaning and cleaning validation at your facility with this free, 100-page e-book, written by a global team of cleaning validation experts, pharmaceutical toxicologists, statisticians, and Six Sigma professionals.