PHARMACEUTICAL & MEDICAL SUPPLIES MIXING AND BLENDING

Ross serves the requirements of the Pharmaceutical industry, in virtually every industrialized country around the world. We have the experience and production capacity that no other manufacturer of specialty mixing and blending equipment can match.

In the USA alone, we operate five plants, an analytical laboratory and a vigorous R&D program. Overseas, Ross pharmaceutical equipment is being built in our own factories in China and India. Typical applications include mixing, blending, particle size reduction, emulsification, homogenization, powder induction, vacuum processing and more.

Specifications that define a mixer built for a pharmaceutical application reflect a combination of industry standards, and the mixing functions needed for that particular application. A sub-micron emulsion, for example, requires high-shear agitation, vacuum and usually a heat-transfer system. The size of the mixer is determined by the throughput required. To guard against batch-to-batch contamination, CIP and SIP capabilities are usually designed in, along with such devices as air-purged seals and custom designed discharge valves. To ensure a high degree of repeatability and to document the production of every batch, we often add a control system with data-logging capability.

The close connection between specific performance requirements and equipment features is the logical starting point for equipment design. But today, the challenge of specifying and designing a high-performance mixer is more than a two-dimensional process. We regularly address performance needs that are much broader than one particular mixing application. In fact, we often custom design pharmaceutical equipment to meet production needs that have not yet been imagined.

CONNECT WITH CHARLES ROSS & SON COMPANY

|

710 Old Willets Path Phone: 631-234-0500 |

CONTACT INFORMATION

Charles Ross and Son Company

710 Old Willets Path

Hauppauge, NY 11788

UNITED STATES

Phone: 631-234-0500

Fax: 631-234-0691

Contact: Sales

APPLICATION NOTES

-

Enhance production efficiency by aligning mixing technology with material viscosity. Implement automated controls and advanced powder injection to reduce errors and energy costs.

-

Learn how you can simplify mixer selection for a particular capsule-shell formulation by considering the formulation's viscosity and the appropriate level of shear.

-

Explore the benefits of preparing liquid supplements in a multi-shaft mixer designed for bulk agitation, high-speed solids dispersion, and superior heat transfer.

-

Multi-shaft mixers are versatile systems used in the production of pharma and medical products. Here, we discuss equipment features commonly supplied on multi-shaft mixers for sanitary applications.

-

In the processing of ophthalmic solutions, high-shear mixers are utilized for dissolving salts as well as dispersing viscosity enhancers, antioxidants and other additives.

-

Designed for high-speed powder dispersion, the Ross Solids/Liquid Injection Manifold Mixer is well proven in the preparation of tablet coatings.

-

A majority of pharmaceutical gels are shear-thinning semisolids prepared by dispersing hydrophilic polymers into an aqueous vehicle. Proper mixing requires a good balance between agitation and shear.

-

Dry blending is an indispensable operation in the manufacture of multivitamins, sports supplements, herbal extracts, meal-replacements, green food powders, and other nutraceutical products.

-

The growing demand for prescription and over-the-counter transdermal products encompasses a wide range of uses and conditions, from motion sickness and smoking cessation, to hormone replacements and pain management.

-

Planetary mixers are ideal for wet granulation processes. Advantages include "one-pot" processing, high uniformity and yield, predictable performance, and ease of cleaning.

-

Viscous products possessing shear-sensitive behavior, fragile components or abrasive properties require gentle but thorough mixing.

-

Granulation requires the addition of binding fluid/adhesive to a blend of powders. The liquid is added at a pre-determined rate to the batch while it is being mixed.

-

Consider upgrading your emulsification and homogenization processes to an ultra-high shear mixer to obtain finer droplet sizes and handle higher viscosity emulsions.

-

Tumble blenders deliver highly accurate and repeatable mixing of powders, granules and even low-viscosity slurries. In addition, this style blender enables complete discharge and easy cleaning.

-

Vitamin and mineral supplements in solid dosage forms undergo mixing, granulation and drying processes which have traditionally required multiple dedicated pieces of equipment.

-

The Ross Solids/Liquid Injection Manifold (SLIM) Technology is well proven for fast and complete hydration of pectin powders as well as other kinds of thickening agents.

-

High shear mixers are used to prepare emulsions under 10,000 centipoise. The single-stage design features a four-blade rotor turning at tip speeds around 3,000-4,000 ft/min.

-

Explore an array of mixers and mixing technologies that can help you throughout the cannabis product manufacturing process.

WHITE PAPERS

-

Mixing equipment employed in the production of pharmaceuticals and medical devices deal with a higher level of complexity because their use is more specialized. Not one design fits all.

-

The aim of this paper is to provide a brief compilation of technical and practical information on high viscosity mixing based on the collective experience of Charles Ross mixing experts.

-

In processing plants around the world, ribbon blenders are used to mix many thousands of products, from fertilizers and plastic resins to flavored coffees and cosmetics. By Charles Ross and Son Company

-

In processing plants around the world, ribbon blenders are used to mix many thousands of products, from fertilizers and plastic resins to flavored coffees and cosmetics. By Charles Ross and Son Company

-

A semi-continuous process is beneficial to maintaining a clean and streamlined batch mixing operation without compromising the level of control over discrete units of production. The semi-continuous mixing procedure is achieved by utilizing a change-can design mixer. With multiple vessels, one mix could be at the loading stage, another under the mixer, another at the discharge step, and yet another at the cleanup stage. By Christine Angos-Banaszek, Application Engineer, Charles Ross & Son Company

-

Surface-active agents, or surfactants for short, are compounds that lower the surface tension of a liquid and lower the interfacial tension between two liquids. Surfactants are amphiphilic in nature, possessing both hydrophilic and lipophilic properties. The unique combination of these opposing properties in the same molecule is what enables a surfactant to reduce surface and interfacial tensions. Submitted by Charles Ross and Son Company

-

An innovative rotor/stator generator developed at Ross is capable of ultra-high shear mixing, dispersion, emulsification, homogenization and particle size reduction. Unlike other mixers that apply intense shearing action, this one does not force manufacturers to choose between a high shear rate and a high flow rate. It delivers both.

-

Work in a typical lab is aimed at achieving a long list of goals in product development. But every aspect of business in the lab is also driven by a collection of chronic shortages. Space for equipment in the lab is always tight, and virtually every lab manager will tell you that his lab is under-funded. During the last few years, new directions in product development have added to the challenge of managing R&D

-

The editorial staff at Pharmaceutical Online recently sat down with Gladwyn Lagman to discuss Charles Ross and Son Company and the trends in the pharmaceutical manufacturing industry. Gladwyn is the Executive Vice President of Charles Ross and

Son Company in Hauppauge, NY. Submitted by Charles Ross and Son Company

The editorial staff at Pharmaceutical Online recently sat down with Gladwyn Lagman to discuss Charles Ross and Son Company and the trends in the pharmaceutical manufacturing industry. Gladwyn is the Executive Vice President of Charles Ross and

Son Company in Hauppauge, NY. Submitted by Charles Ross and Son Company

-

A few years ago, the process of selecting a mixer for most applications was straight- forward. When increased demand required an increase in production, process engineers were naturally inclined to choose the type of mixer that had worked before in the same application. When they began talking to equipment manufacturers, their questions focused on capacity, auxiliary equipment, projected delivery and price. Many tested equipment before signing a purchase order.

ARTICLES

-

Optimize complex batching with multi-shaft mixing technology. Achieve rapid powder dispersion, uniform heating, and automated discharge for high-viscosity pastes and gels.

-

Vertical integration and elite material selection ensure industrial equipment longevity. Prioritize custom engineering and internal quality control to solve complex processing challenges.

-

ROSS recently completed the largest Double Planetary Mixer in its US history, a Model DPM-750 capable of mixing up to an impressive 750 gallons per batch and engineered with safety features for a Class I, Division 1, Group D hazardous environment. This heavy-duty mixer delivers the robust agitation required for ultra-high viscosity materials while adhering to demanding safety standards.

-

Customizable ROSS Ribbon Blenders deliver reliable mixing of food, nutraceuticals, cosmetics, personal care products, in addition to chemicals, plastics, building materials and agricultural products.

-

A well-proven tool for robust mixing of high-viscosity materials, the ROSS Double Planetary Mixer delivers exceptional performance through its unique agitation system and adaptability, while meeting explosion-proof requirements. The Model DPM-150 is a heavy-duty mixer that can process formulations ranging from 20 to 150 gallons, with viscosities exceeding 6 million centipoise. It is one of several ROSS production models serving thousands of pharmaceutical, aerospace, adhesives, sealants, composites, and specialty chemical manufacturing plants around the world.

-

Engineered for applications requiring advanced mixing capabilities, the ROSS VMC-300 combines three independently driven agitation systems in one unit. This multi-shaft mixer integrates anchor, high-speed disperser, and axial flow turbine technologies to effectively manage complex and viscous formulations in the pharmaceutical, food, cosmetic, coatings, adhesives, composites, and other specialty chemical industries.

-

ROSS is pleased to announce the completion of a custom Coaxial Mixer. Through an innovative concentric-shaft configuration, this advanced system effectively blends, disperses, and homogenizes materials by combining two synergistic agitation technologies. In a variety of industries, such as adhesives, sealants, coatings, composites, cosmetics, and pharmaceuticals, the coaxial design enables processors to handle a wide range of rheologies while offering a range of different flow patterns.

-

Ross Mixers offers refurbished equipment through its factory reconditioning program.This initiative allows customers to purchase mixers that have been meticulously restored to "like-new" condition by the company's original equipment manufacturer (OEM) team.The reconditioning process includes thorough inspection, repair, re-polishing, and testing of all components to ensure optimal performance.

-

ROSS is pleased to announce significant price reductions on the Series 100 and Series 500 Production Batch High Shear Mixers.

-

The ROSS VersaMix VMC-320 is a versatile multi-shaft mixer for processing viscous solutions, offering powerful agitators, customizable controls, and semi-continuous operation with robust safety features.

-

ROSS Ribbon Blenders are used throughout the process industries for the efficient and effective mixing of powders, granules, pellets, grains and other bulk solids. Available in lab scale to full production models, these machines are built to handle a wide range of bulk densities and can be customized for heavy-duty and sanitary applications.

-

It is with great sadness that we announce the passing of Richard Ross, former president of Charles Ross & Son Company, on September 14, 2024. Rich was a visionary leader who played an instrumental role in shaping the company’s future and global success.

-

Built to handle a wide range of formulations and viscosities, the ROSS FDA-50 Fixed Tank Dual Shaft Mixer is a custom-design agitated pressure reactor ideal for processes that require meticulous control over mixing, temperature, and pressure in a compact and portable module. The stainless steel type 316 dished bottom vessel and removable dished cover can accommodate internal pressures up to 100 psi, stamped according to ASME Section VIII, Div. I.

-

ROSS Dual Shaft Mixers are versatile, robust and cost-effective systems engineered for accurate processing of high-performance formulations across a wide range of rheologies, solids loading, operating temperatures and pressures.

-

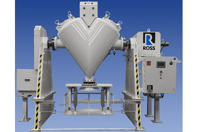

Offering a high level of precision and consistency, ROSS V Cone Blenders utilize diffusion as the main mechanism for mixing. As the V shaped vessel rotates on its horizontal axis, batch materials cascade down, distributing particles over a freshly exposed surface.

-

Fully Rebuilt to perform like brand new, ROSS-reconditioned Double Planetary Mixers are dependable workhorses for high-viscosity and heavy-duty applications. The pictured Reconditioned Model DPM-4 has been meticulously restored to as-new working condition and offers the same standard one-year warranty as a new ROSS Mixer.

-

Capable of processing viscous solutions, dispersions, suspensions, and emulsions with viscosities in the hundreds of thousands of centipoise, the ROSS line of VersaMix Multi-Shaft Mixers is built for longevity, speed and efficiency. The ROSS VMC-100, pictured below, is designed for vacuum operation up to 29.5”Hg and supplied with interchangeable 100-gal mix cans, each fabricated with a 50-psig ASME-code stamped jacket for heating/cooling via glycol. The custom electro-hydraulic system is engineered to fully raise the motor drive in 15 seconds.

-

ROSS Mixers, a leading provider of US-designed and manufactured mixing equipment, offers a Trial Rental Program which offers process managers a powerful tool for optimizing R&D projects before committing to substantial capital investment.

-

The ROSS line of Double Planetary Mixers, which come in a wide range of configurations and sizes ranging from ½ pint to 750 gallons, are dependable workhorses for mixing thick, sticky, or putty-like materials. The pictured Sanitary Double Planetary Mixer Model DPM-4S and Sanitary Discharge System Model DS-4S are fully customized and engineered for efficient processing of medical-grade silicone formulations in a portable workstation.

-

ROSS VersaMix Multi-Shaft Mixers are proudly designed and manufactured in the U.S. to optimize the processing of medium to high-viscosity products. These versatile mixers exhibit outstanding performance and deliver exceptional efficiency across a wide range of applications with viscosities ranging up to several hundred thousand centipoise such as pastes, gels, slurries, and suspensions.

-

A proven workhorse used throughout the process industries, the ROSS V Cone Tumble Blender utilizes diffusion mixing to deliver low impact, highly accurate, and repeatable mixing of powders, high-density powdered metals, granules, pellets, and other free-flowing solids.

-

This laboratory high shear mixer consists of a single stage four-blade rotor that turns at high speed within a stationary stator. Learn how the design promote continuous flow, fast mixing, and more.

-

This double planetary mixer includes two blades that rotate on their own axes while simultaneously orbiting the mix vessel on a common axis. Watch to learn more about this mixing technology.

-

Known worldwide for heavy-duty robust construction, high quality materials, and fine craftsmanship, these ribbon blenders meet the toughest standards for quality and long-term performance.

-

Explore robust and versatile multi-shaft mixers used throughout nearly every process industry. These mixers accommodate a range of shear input and viscosities up to several hundred thousand centipoise.

-

Discover an original equipment manufacturer (OEM) that has the unique capability to provide standard and custom designed mixers to meet your diverse processing needs.

-

OSS Three Roll Mills, used for high viscosity dispersions in many industries, feature true heavy-duty construction, precision workmanship and ANSI 2017-compliant controls package.

-

ROSS is pleased to announce the launch of its newly redesigned website. Mixers.com is faster than ever before, easier to navigate and contains more product information.

-

Designed to minimize risk and maximize productivity, ROSS Ribbon Blenders meet OSHA standards with safety shaft guards (no external moving parts) and limit switches that prevent operation of the agitator when any cover or manway is open. In addition, safety grating can be installed on dedicated charge ports or across the entire blender opening for extra protection and to make it easier for operators to dump bags of dry raw material into the blender.

-

The ROSS X-Series Inline Ultra-High Shear Mixer is designed for efficient high-throughput emulsification, dispersion, and homogenization.

-

ROSS VersaMix Multi-Shaft Mixers with Solids/Liquid Injection Manifold (SLIM) Technology enable fast and efficient large-scale powder dispersion into low-viscosity liquids including resins, oils, melted waxes, emulsions, and aqueous solutions.

-

The ROSS Inline Ultra High Shear Mixer 700 Series is designed for challenging shear requirements, a more efficient alternative to colloid mills which generally suffer from low throughput.

-

Gain insights from a pharmaceutical equipment manufacturer on factors cannabis manufacturers should consider when they're looking to purchase a mixer.

-

ROSS engineers custom blending systems incorporating ergonomic material handling accessories, including bag dump workstations.

-

The ROSS Double Planetary Mixer is ideal for high-precision mixing, granulation and vacuum drying all in a single vessel.

-

ROSS recently designed a new skid system capable of mixing and pumping low to moderately viscous products. The Model VSL-400 design is a custom conical vessel on a movable skid with a progressive cavity pump rated for 10-30 gallons/minute.

-

The ROSS Double Planetary Mixer is available in a reverse-lift design which raises the vessel to the mixing position, rather than lowering the agitator assembly. A reverse lift facilitates improved rigidity and more uniform blade-to-vessel clearances without relying on the floor to be completely level.

-

ROSS inline high shear mixers from 1 through 250 HP accelerate mixing, emulsification and homogenization in both recirculation and continuous modes. A mobile skid allows these machines to be used anywhere in a plant, saving time and money by eliminating the need for multiple mixers separately dedicated to each vessel or product

-

Conventional agitators are unable to create the fluid circulation necessary to disperse 4%+ powdered CMC dispersions. The consequence of insufficient agitation is the formation of non-dispersed lumps.

-

Topics of this webinar include dry blending, high speed mixing, and batch mixing applications for pharmaceutical manufacturing. This webinar addresses the current challenges facing the industry , as well as new innovation that will help with any issues manufacturers are facing.

-

The challenge of producing high-quality emulsions, solutions, and dispersions can sometimes be a moving target due to changing market demands, consumer behavior, and product requirements. By Christine Banaszek, Charles Ross and Son Company

-

Custom Pharmaceutical Sanitary Tanks, Storage Vessels, Reactors And Transfer Vessels Offered By RossDuring the last two decades, Ross has grown to be one of the best-equipped and most highly respected custom fabricators in North America.

-

Designed for multiple mixing requirements such as high-speed dispersion, emulsification and particle size reduction, the Ross VersaMix (Triple Shaft Mixer) is now available with a Solid/Liquid Injection Manifold or S.L.I.M.™ System.

-

Warren Ang– Product Manager has announced the completion of a new model of the popular line of Ross Ribbon Blenders. The new model is designated as the "42NSD”.

-

Article: Understanding Surfactants And New Methods Of Dispersing Them

-

Charles Ross and Son Company recently introduced a new model of its proven line of Double Planetary Mixers. This new design is unique in that the mix can is raised to a fixed drive assembly. The mix can is normally positioned on the floor with the drives being raised and lowered via a hydraulic lift

-

The Sanitary Blenders are all manufactured in type 316 stainless steel and are polished to a 150 grit finish to enable easy cleaning between batches

-

Wetting out powders like fumed silica, TiO2, gums and thickeners is one of the toughest challenges our customers face – in virtually every industry we serve, from foods and pharmaceuticals to coatings and the CPI

-

The specifications that define a mixer built for a pharmaceutical or cosmetic application reflect a combination of industry standards and the mixing functions needed for that particular application

-

In processing plants ribbon blenders are used to mix many thousands of products, from fertilizers and plastic resins to flavored coffees and cosmetics