Dow Introduces Dowtherm MX at Chem Show

Dowtherm MX takes its place among Dow's high-temperature heat transfer fluids.

"If you're running a low-pressure system between 550 and 620°F, Dowtherm MX heat transfer fluid is the best choice available," says Tom Frazier, senior market manager for Heat Transfer Fluids in Dow's Specialty Chemicals business group.

Dowtherm MX provides great thermal stability over its entire normal application range of -10°F to 625°F (-23°C to 330°C). Moreover, it is pumpable down to -10°F (-23°C), which minimizes start-up and shutdown problems and, Dow expects, the need for costly heat tracing.

Moreover, unlike other moderately priced synthetic organic heat transfer fluids offered as alternatives to higher-performing hot oils, Dowtherm MX fluid has a very high atmospheric boiling point of ~ 622°F (~ 328°C). As a result, it can be used in non-pressurized systems operating at temperatures up to 620°F (327°C). This capability, coupled with physical properties very similar to those of higher-performing hot oils, makes Dowtherm MX a potential drop-in replacement for hot oils.

Dow's family of high-temperature heat transfer fluids, with Dowtherm MX represented by the yellow bar at the bottom.

Hot oils are long-chain hydrocarbon-based alkanes with only incidental (if any) aromatic content. These relatively low-cost fluids include white mineral oils, mineral oils, hydrotreated oils, severely hydrotreated oils, synthetic mineral oils, oligomers of alpha-olefins, and lube-oil base stock. When they are considered for use as heat transfer fluids, there are very few significant differences between each type of hot oil because their chemistry and molecular weights are so similar. Hot oils with approximately the same molecular weight will have physical properties that are essentially equivalent.

The Dowtherm MX difference, according to development chemist John Cuthbert, is in the fluid's chemical construction: straight chain aliphatic groups bonded to a phenyl ring. So while the molecular weight (and heat transfer capabilities) are equal to those properties in any number of hot oils on the market, the phenyl ring imparts very high stability. "Straight-chain C18 to C20 oils don't come close," Cuthbert stated.

When used as heat transfer fluids, hot oils are typically selected for zero-pressure, liquid-phase systems whose operating temperature range normally does not exceed 550°F (288°C). Such applications are in petrochemical refineries or polystyrene plants, where thermal fluids may be heated up to run distillation columns and reboilers, or to pre-heat feed to a reactor.

Trouble Beyond Normal Range

However, when such systems are required to run beyond their normal range to temperatures as higher than 550°F (288°C)—for example to increase throughput or production—hot oils degrade very rapidly and make coke and carbon solids in the piping. The resultant system fouling could lead to costly downtime.

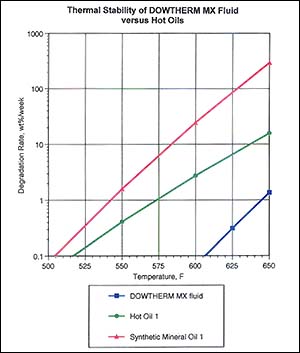

Because it is based on aromatic chemistry, Dowtherm MX is inherently more thermally stable than any hot oil. In tests conducted by Dow (see graph), Dowtherm MX demonstrated substantially better thermal stability than currently available, higher-performing hot oils, and even more so at the upper end of the hot oils' acceptable use range, temperatures around 550°F (288°C).

Dowtherm MX is between 40 and 360 times more thermally stable than hot oils tested at 600°F. At 550°F, a normal temperature for hot oils, Dowtherm MX was up to 650 times more stable than hot oils tested.

Additional physical properties include a flash point of 329°F (165°C) and an autoignition temperature of 788°F (420°C). Dowtherm MX is non-corrosive to common metals and alloys, thus assuring compatibility with most heat transfer systems.

In addition to reduced system fouling, Dowtherm MX fluid provides several other long-term economic advantages over higher-performing hot oils: smaller heat exchangers, possible elimination of costly heat tracing, lower fluid makeup requirements, and expanded changeout intervals. In the event that the Dow fluid needs to be changed out, customers may receive credit toward the purchase of their new fluid through Dow's fluid return program.

To complement the long-term performance and economic advantages of Dowtherm MX, Dow will provide technical support including technical backup in the design phase (during operation and after shutdown, as needed), and free analytical testing to monitor fluid condition.

For more information: John B. Cuthbert, Development Associate, Thermal Fluids TS&D, The Dow Chemical Co., Larkin Lab, 1691 N. Swede Rd., Midland, MI 48674. Tel: 517-636-3251. Fax: 517-638-9241.

By Angelo DePalma